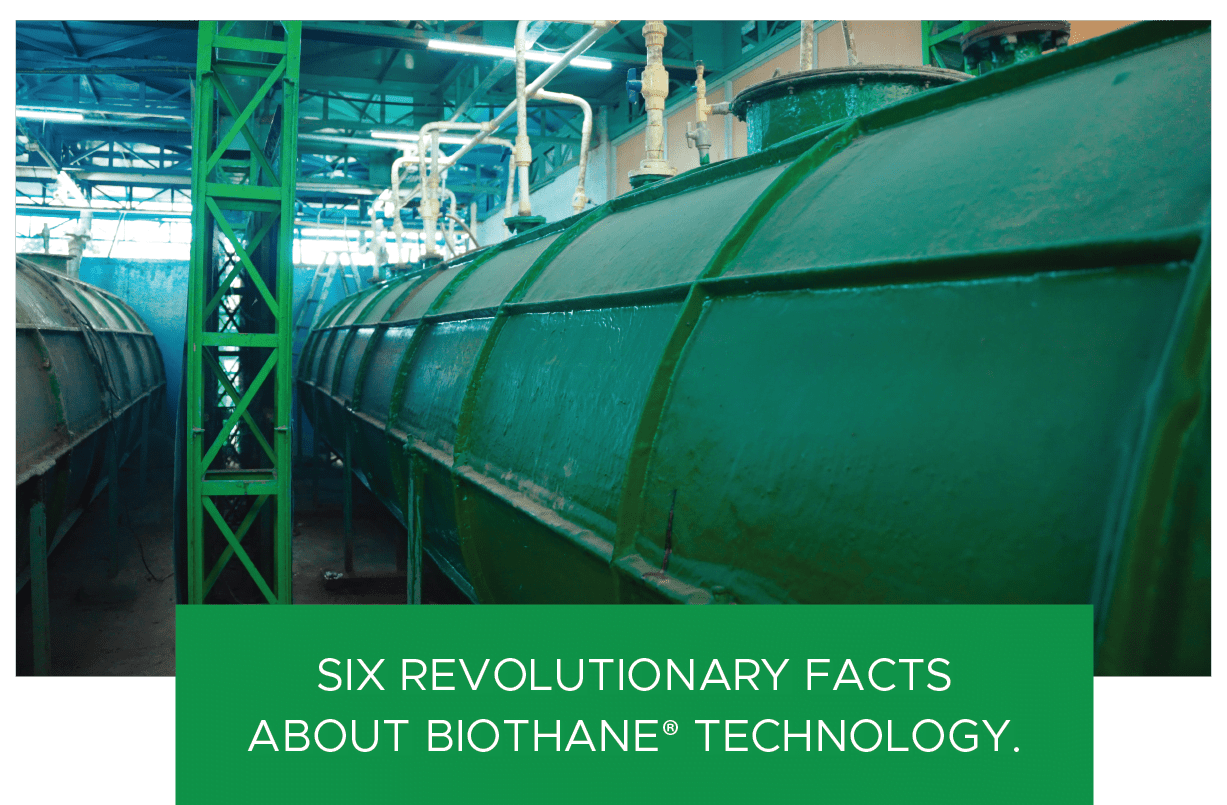

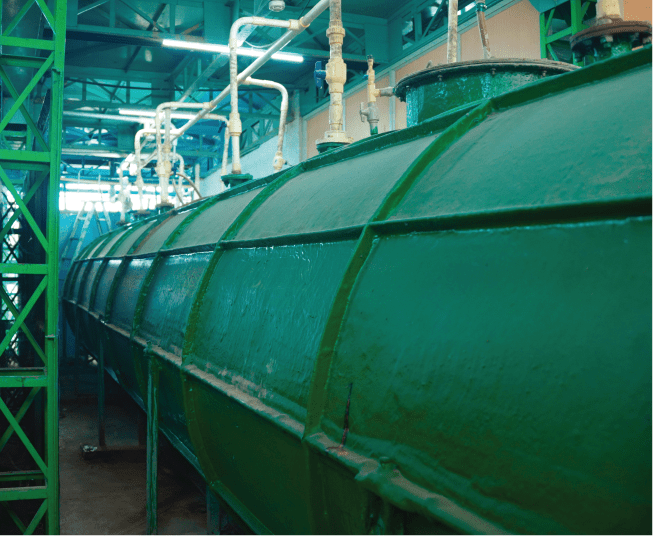

Biothane®. the next-gen bioenergy solution.

- Biothane® helps to produce methane that’s 97% pure.

- It employs a distinctive proprietary technology known as the Microbe Incubated Bio Reactor (MIBR).

- Green energy leaders are spearheading carbon neutrality and turning biomass to wealth with Biothane®.

- Biothane® helps to produce methane that’s 97% pure.

- It employs a distinctive proprietary technology known as the Microbe Incubated Bio Reactor (MIBR).

- Green energy leaders are spearheading carbon neutrality and turning biomass to wealth with Biothane®.